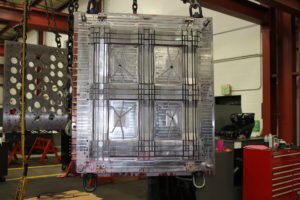

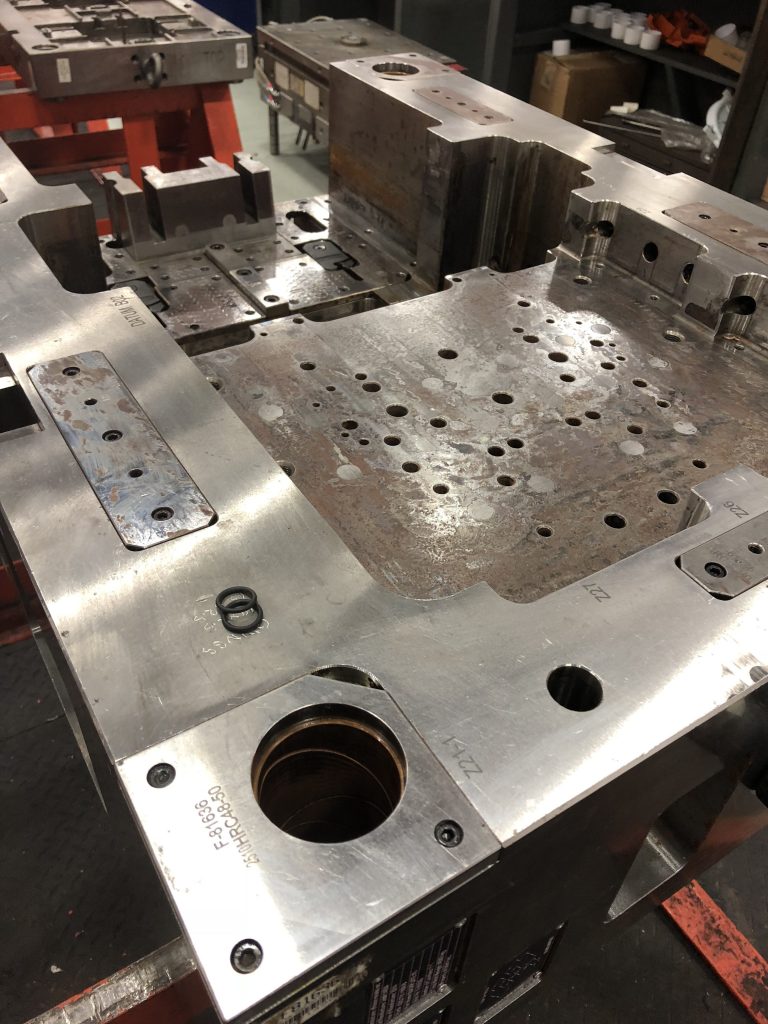

Production Tool Building & Custom Machining

When it comes to production tool building, the team at Decatur Mold Tool & Engineering, Inc. has unmatched expertise. How have we surpassed our competition in this field? It comes from the fact that we were founded as a production tool building firm way back in 1966, and have kept it the core of our business for more than half a century.

After prototype tooling has been tested and your product is ready for a full-scale production run, you need to make sure you invest in the best-of-the-best in production tooling. Contact our custom machining experts to get the best results consistently and at a very competitive rate.

The Different Mold Classes

The Society of the Plastics Industry (SPI) defines prototype tooling as Class 105 molds. That means these molds are designed only to serve as a proof of concept, and should only be used for production runs of 500 cycles or less. These molds are designed from softer materials and often omit more complex aspects so that they can be machines as quickly and cost-efficiently as possible.

A true production tool will be a Class 101, 102, 103, or 104 rated molds, each progressively stronger but subject to more requirements. They break down as follows:

- Class 104 - This mold is designed for a production lifespan of 100,000 cycles or fewer, and for mold materials that are relatively nonabrasive. The mold can be machined from virtually any metal.

- Class 103 - Designed for medium-sized production runs of 500,000 cycles or less, Class 103 molds have base hardness requirements of 8 R/C and cavity/core hardness of 28 R/C.

- Class 102 - These molds are designed for high production runs, 1,000,000 cycles or less, and molding of abrasive materials. Hardness requirements are nearly double that of Class 103 molds.

- Class 101 - Designed for very high production runs of more than 1,000,000 cycles, Class 101 molds have similar hardness requirements as Class 102 molds. There are additional requirements as well, such as guided ejection, wear plates, and temperature control.

Production Tool Building with Decatur

At Decatur Mold, we can build quality production tooling to meet any SPI Class guidelines. We have a full team dedicated to production tool building, including project managers, engineers, designers, and other personnel.

The team has access to a full range of state-of-the-art design software and production equipment: CNC mills, lathes, drills, spotting presses, and more. With these capabilities, there are no features—shapes, geometries, surface textures, and heat treatments—that we cannot accommodate.

We also understand your need to balance quality and cost. To help facilitate production tool building on all budgets, we offer three different build options: fully domestic production, offshore production by our trusted partner in Shenzhen, China, or a hybrid China-U.S. production.

Learn More

Our capabilities and services go far beyond what is detailed here. Steel certifications, tool sample tests, and progress reports are also available. To learn more about Decatur Mold and our full range of production tool build capabilities, contact us today.